cross-posted from: https://lemmy.world/post/2026026

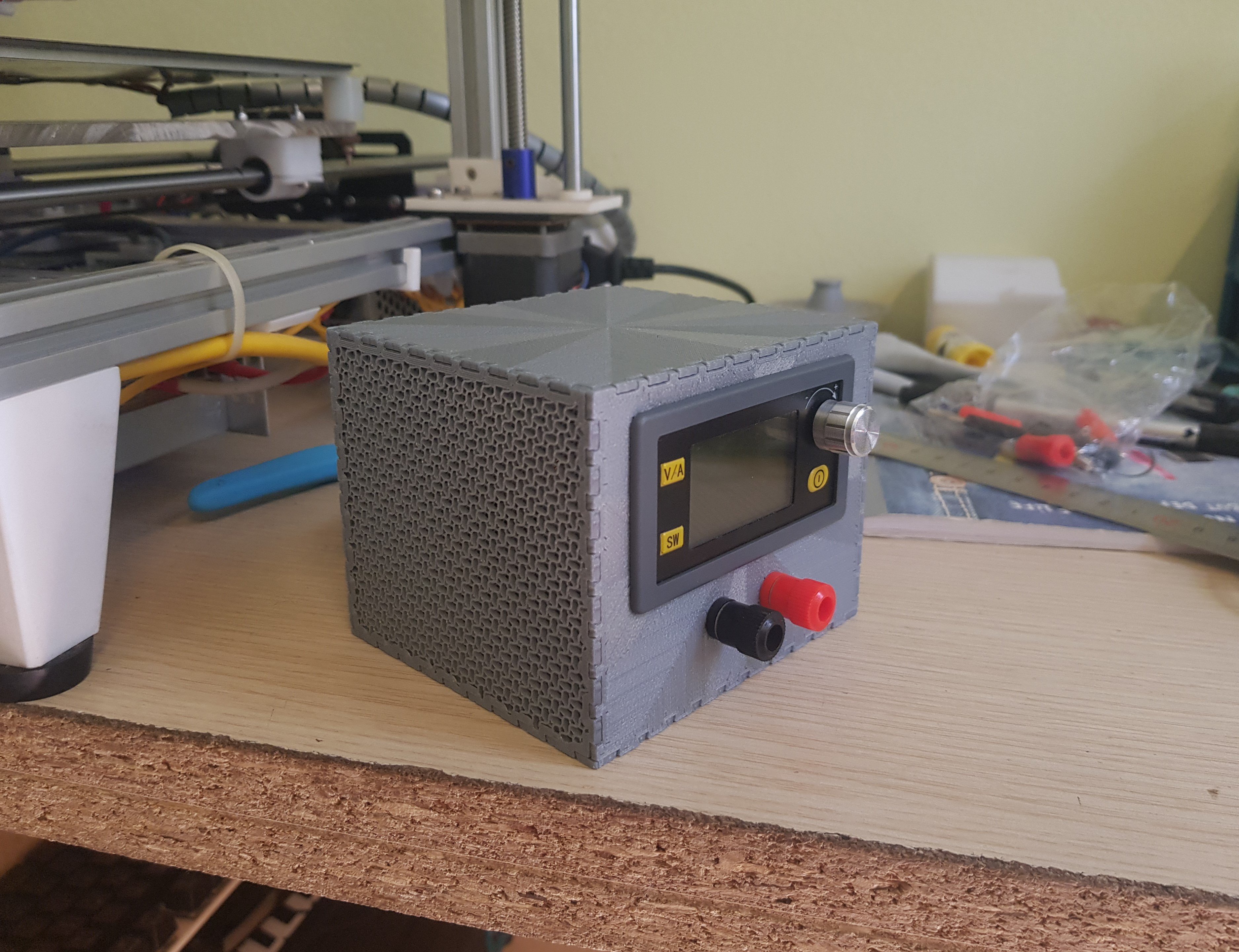

The box is not printed as a single piece, but 6 modular plates joined with dovetail joints. Individual plates are relatively flimsy, but once assembled the box is rock solid.

This way, it is much faster to print, and is stronger since the layer lines are protected. It also let me experiment with infill for some cool effects.

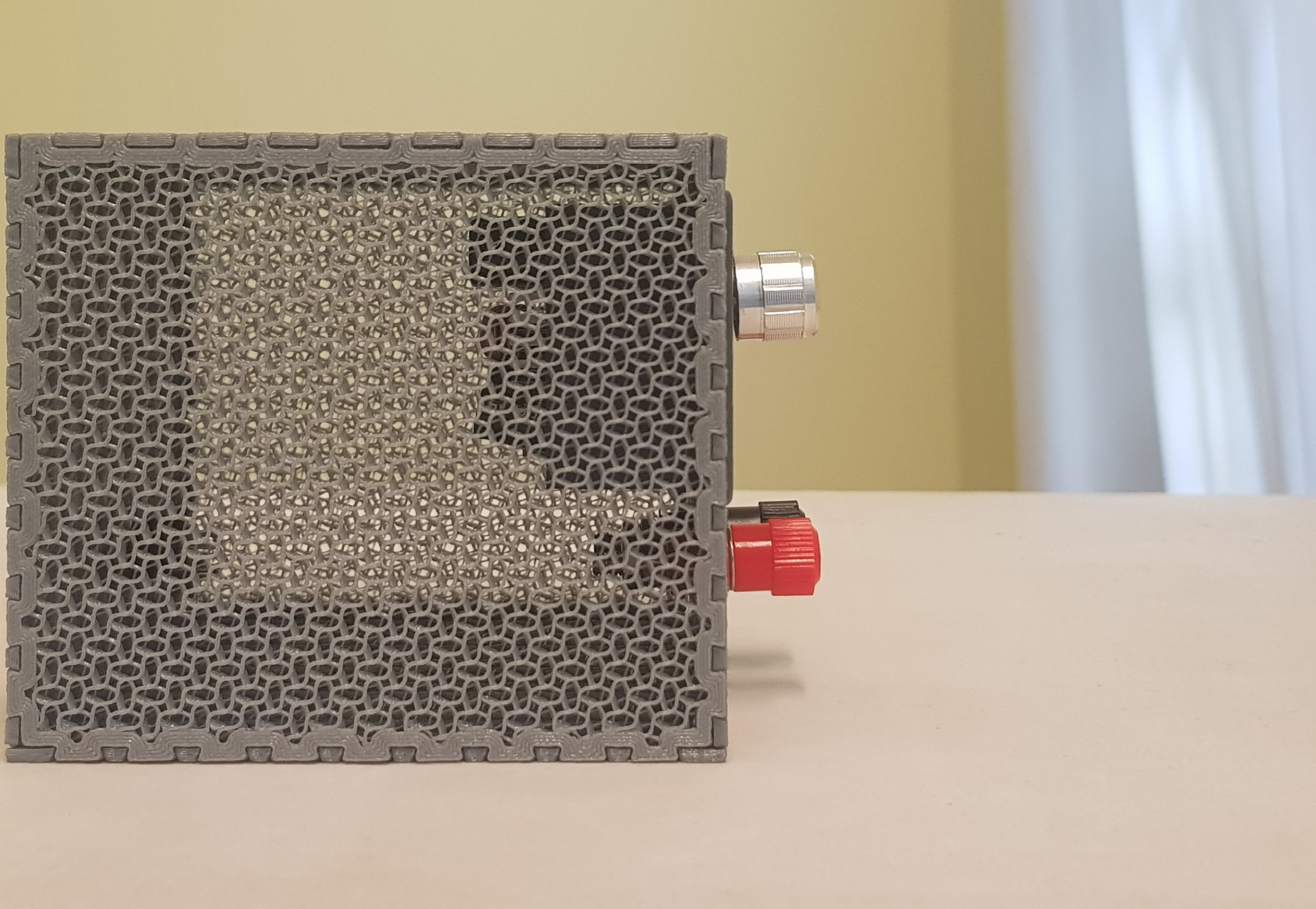

Closer look at the top pattern

Front pattern

You can’t see from the images, but each plate is printed without top layers, which make it even faster to print and use even less filament, compared to a vertical wall of the same weight.

The back

Gyroid air vent

Interesting as a funcional print.

I suffer a lot for some imperfections on my prints but I see you embrace them with pride.

Congrats for the box idea, I’ll take my notes if someday could make good use of them.

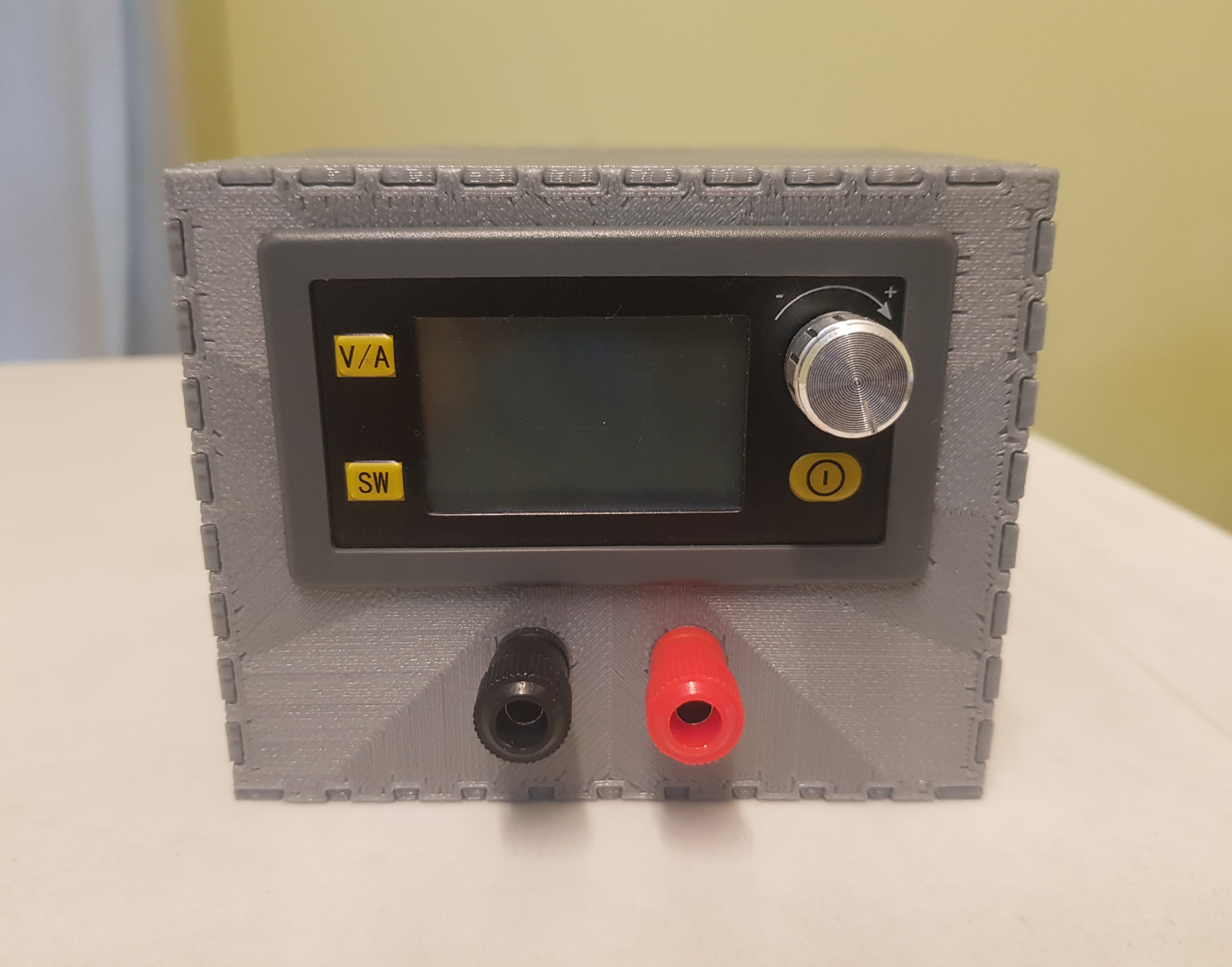

This is only a prototype, you can see there are no wiring inside. The artifacts are because I print at 150m/s and 5k acceleration, on a bed slinger.

Very cool. Would you be worried at all about heat?

That’s the neat thing! If passive convection can’t do the job, I just have to print a new top plate with fan mount.

True. Is it glued together or do the joints just hold it all together?

It is held together completely by the joint. These dovetail joint are known to be very strong reliable.

Also Im guessing you just printed the box, not the little black and red connectors, or the black piece that holds the screen or the little yellow buttons? Just wondering as I might try something similar some day.

Yes.

Do you have a link or something with the components you used for the power supply itself? I’m interested in making one for myself!

The interface module which do everything is just the cheapest one I found locally. It called a buck boost module but that doesn’t really narrow it down. Other than that it’s just 2 binding posts and whatever supply you want. I used a barrel jack plug to reuse my old laptop charger.