I recently bought a junk bike. I want to slowly fix it up myself for two reasons: 1. To have a nicer bike. 2. To learn about bike maintenance. I’d like to improve it slowly (weeks or months) while keeping it functional. What order should I consider improvements?

I’ll elaborate. When I first bought the bike, I tuned the brakes (linear pull). I struggled. I realized brake tuning was difficult because my wheel wasn’t aligned. In retrospect, I should have straightened/replaced the wheel before tuning the brakes. I’m wondering if there are any insights you could provide about the order I should tackle this project (e.g., wheel alightment before brakes).

deleted by creator

Wow, that looks like a ton of info. Thanks.

I did a similar thing many years ago, so take this with a grain of salt.

Your wheels need to be true. Have a pro do it at a shop, because that’s a skill that takes practice and you don’t want to fuck it up. If your wheels aren’t true, everything else will suck.

Your bike has four important sets of bearings, in order of importance: rear axle, bottom bracket, front axle, and head tube where the fork inserts. They should all spin freely and with minimal resistance. Whether you can service them or not depends on the style and make for each component. You might be able to take them apart, clean out the gunk, and re-apply grease, but again this is something better left to the experts. If you fuck up your bearings, your buying a bunch of new parts.

Once the wheels are true and the bearings are clean and lubricated, you can start on the DIY stuff. Changing a tire is probably the first thing, but tuning your brakes is also a great place to start. Flip the bike and align the calipers, replace the pads if needed, and then adjust tension until you can stop the bike with a gentle squeeze.

You should also get familiar with your derailleurs and shifters, because fine-tuning your gears will sve a lot of frustration. You can replace the cables in your brakes and shifters the same way you replace the brake lines, but remember that the cables are not typically interchangeable. Brake cables must pull, but shift cables pull and push. Some people like to clean and lubricate old cables, but I’ve always felt like that’s a lot of work to save $2 worth of cable.

Last thing is making sure all of the clamps and bolts are tight. Common problem areas are the seat post and the handlebars. Make sure you can loosen the seat post clamp, the headset and the stem, and adjust heights and angles as needed. Most importantly, you should be able to tighten them down so they don’t move or slip. You don’t want to overtighten, because that’s how clamps and bolts get stripped, but you should be able to get it tight by hand or with tools you carry with you. Older bikes can have worn clamps or bolts, and the posts or bars can slip. You don’t want to be in traffic when your stem comes loose and you can no longer steer.

One thing people tend to focus on is the chain, but unless you are splashing through mud, you probably don’t need one of those fancy machines or expensive lubricants. Wipe off any gunk with a rag, and then apply chain grease once every few months, maybe sooner if you ride in the rain or around a lot of sand or dust. If your derailleurs are properly tensioned, your gears are in good shape, and there’s no rust or bends in the chain, it’s probably fine.

Fantastic comment. Only item I might disagree on is bearings IF the bike has cartridge bearings as those are easy to work with. If it’s cup and cone/loose ball then yea, I’d recommend just letting the shop do it only because cone wrenches are a pretty specific tool.

Lots of bike shops (especially community bike shops) offer inexpensive courses on bike maintenance which are a great option for learning.

Great suggestion. I’ll definitely look around for local classes.

Thank you! I think this is exactly what I needed.

I like the concept of drawing the line between DIY and “just take it to the shop”. Based on my minimal knowledge, I purchased a bike that looked like it only needed DIY fixes. Sounds like I should take a closer look at these wheels before I move forward.

Yeah, some things I look for when buying used:

- are the wheels true? - spin it and see if it wobbles; also check tension of a few spokes, they should all feel taut

- is there resistance when pedeling? - change to the lowest gear, lift back tire off the ground, and spin the pedals

- are there any cracks or damage to the frame? - less of a concern for steel frames, a huge concern for carbon fiber, and moderate concern for aluminum

- does it shift smoothly? - run through all of the gears; if there’s multiple chainring cogs, you only need about half of the rear gears to work well per cog

- is the chainring damaged? - it’s not that hard to replace, just kind of expensive; a chainring in good condition will look even on both sides of the teeth, a worn one will look like a shark fin

If there’s frame damage, I just move on to the next. The rest just impacts how much I’ll offer for the bike. I’m not too worried about consumables (brake pads, tires, rear cassette, chain, etc), but the rest can add up.

You’ve gotten a lot of good advice here, however, I don’t think anyone’s mentioned Bike Co-ops. If you have one nearby, it sounds like that would be an ideal spot for you to work on your bike while getting advice from more experienced mechanics.

Sadly, there are no bike co-ops that I know of in my area, but I’ll ask around at some local shops.

That’s definitely a good place to start. You also might want to check out any local Universities/Colleges. My University had a bike shop that was basically a co-op, but it’s officially owned by the Student Union. I took a repair class and regret not continuing to learn by volunteering to work on their donated/salvaged bikes.

The other option might be looking for less formal repair networks. For example I know some groups have repair clinics every-so-often in local parks. Or even local cycling groups, or word of mouth. A lot of people are more than happy to share their passion for bicycles and maybe you can find a mentor.

How out of true were the wheels that the brakes didn’t work? When you say it wasn’t aligned, what wasn’t aligned? You may have an incredibly unsafe BSO instead of something worth fixing up.

The wheels wobbled a few millimeters. This caused the brake pads to touch at various points while the wheel rotated (with the brakes disengaged). I believe the spokes just needed a little adjustments to straighten out the wheel alignment. After briefly adjusting the spokes, the brake now function (albeit poorly) without touching the wheel unnecessarily.

From here, I think I’ll spend some more time finetuning the spokes to make sure the wheel is as straight as possible before further tuning or replacing the brakes.

I am just taking it on short and slow rides around my neighborhood right now. I’m not too worried about safety. I’m not fixing it up as an investment. I mostly a fun project to learn more about bikes.

right on! just be careful you don’t tighten the spokes so much that they poke through the rim tape. I made that mistake and punctured waaay to many tubes. Now I just let my LBS true them. I’m terrible at it and they’ll do it for 10 bucks a wheel.

If you’re content with the wheels I would maybe look at replacing the brake pads next once you can verify that they function well with the trued wheels.

After that, I’d look at the drive train and see what can be done about the indexing on the front and rear derailleurs, limit screws, ect and maybe take the rear hub apart and make sure that is all in proper working order [prongs engage, disengage correctly], give the cassette a good look over for wear [shark fins] and check the chain for stretching [chain tool].

How much rust is on the chain and gears?

After that, maybe look at the bottom bracket and seeing what can be replaced/upgraded to make sure there’s no clicking, rubbing, and making sure you have a solid chain line to the cassette.

I appreciate your insight.

There is minimal rust on the chain and gears. There is quite a bit if discoloration on the gears, but its not rust and doesn’t seem to be a structural concern. The drivetrain definitely needs some work, but it’s functional enough that I’ll probably work on brakes first because they are simpler.

Sounds like I need to get these wheels straightened out first, then I’ll probably fix up the brakes, then the drivetrain.

If there’s some discoloration on the gears, it’s probably worth cleaning that up. Whenever I clean my chain and rear cassette, the bike feels so much nicer to ride.

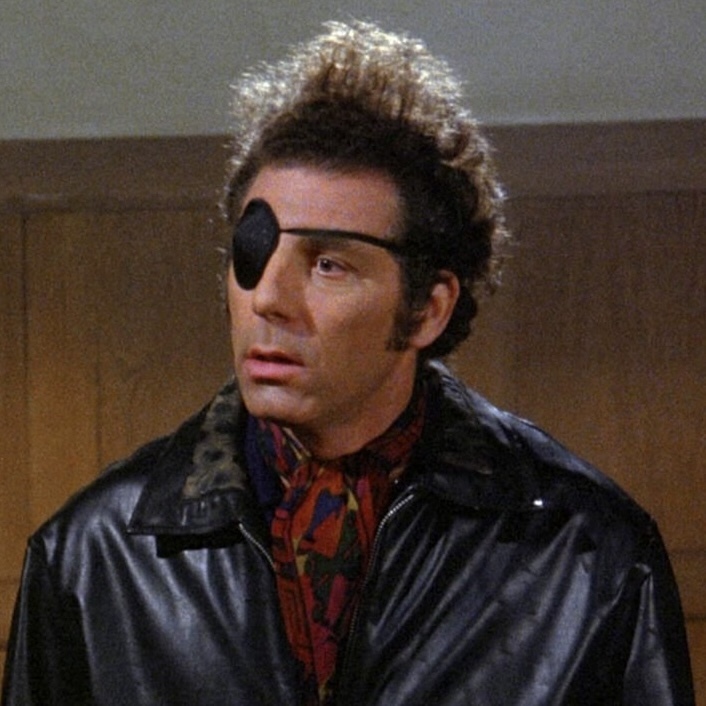

- buy a chain cleaner tool (like this) - $30-40 on Amazon

- Simple Green - $5-10 for a massive jug at a home improvement store - skip if #1 comes with some chain cleaner

- chain lube - $10 at your LBS

My LBS has a kit for $40 that has everything you need, but if you decide to go the Simple Green route (it’s what I use now that the LBS stuff is used up), dilute 50/50 with water. If you’re careful to not get the degreaser in the rear hub or derailleur, you can use the degreaser and a brush to clean the rear cassette (or remove it if you’re worried). Then thoroughly rinse everything with clean water, dry it, and then apply the chain lube. If there was a lot of build-up, this can result in a much nicer ride feel.

Also, get a chain stretch tester, or ask your LBS to check it for you. Riding on a stretched chain sucks and can accelerate wear on your drivetrain. Replacing it is pretty cheap (like $20) and most shops don’t charge much for that service since it only takes a couple minutes.

But it’s far more important to make sure it’s safe, so getting the wheel trued and brakes tuned are the top priority. If you have a friend that likes cycling, you can probably ask to borrow that stuff.

Thanks for the advice. Hopefully I get to this stuff in the next couple weeks after the wheels and brakes.

You must have proper tools. Do not try to hack something that might seem to work in a pinch. This is the primary leverage of why you have a bike serviced in a shop. The tools are expensive initially.

Bikes have minimal componentry that is engineered to be barely sufficient to keep them light weight as the primary design constraint. This is not like other technology where there is more robustness. The right tool for the job is a required item. Don’t use channel locks, adjustable wrenches, box spanners on thin jam nuts, etc.

If you enjoy this and keep riding, don’t wait years to get a $100-$150 portable bike stand – like most of us do. That makes a huge difference for actually maintaining a bike.

If the bike sat for a long time, the spoke nipples may be seized to the spoke threads. If this is the case, truing the wheel may be possible, but this will bite you in the long run. You’ll end up over compensating to get the wheel in shape and this will cause issues that break spokes regularly in the long term if you ride on a scale of dozens of miles weekly. If the wheels are carbon, rebuild them. If they are not, just replace them.

Wheel building gets fantasised as some kind of dark art but that is crazy. I’m a former Buyer for a chain of bike shops; I managed everything but the people. I’m also a former amateur racer, am far better than most mechanics at road bikes, and have always worked on my own, with around 170k miles on bikes since 09. I build my own wheels because they are carbon rims. The price of spokes is why no one builds wheels any more. Buying replacement wheels is cheaper unless the wheels are north of ~$500. It is too much labor and the way spokes are packaged from wholesale distributors makes them unprofitable for bike shops.

The order of adjustments on derailleurs is the important bit.

When you’re in a shop and unsure if a bike is safe to test or ride, like if a customer brings something in or a new kid is assembling bikes, the first step is to face the bars with the front wheel between your knees. Then twist the bars sideways firmly and sharply. This tests that the stem and headset were setup correctly and the bars are not going to slip on the first turn or bump.

Next, you pick up the whole bike with the tires 3-4 inches over the ground and drop it. Anything loose will make a distinct vibrating sound that is bad. Don’t stress about not knowing what this sounds like, you will easily know it when you hear it.

Finally, standing beside a bike, pull the brakes hard and try to push. Make sure it can hold your weight. Pull back and forth a few times to make sure everything holds.

If it passes those tests, and obviously has the stupid simple stuff like air in tires and appears complete, it is at least safe enough to pedal around the block.

Sweet, at least my bike definitely passes the basic safety tests.

Its funny, two hours in and my back is also telling me to invest in a bike stand :D

Thank you for help.

As a shadetree bike mechanic, you might be able to make the wheels true-er, but you might also make it worse. You won’t be able to make them perfect, because that takes tons of practice and the right tooling, so if perfect is what you want, take them to a shop. But if all you need is to make your thrift-store ride ridable, you can get the wheel true enough with some patience.

Thanks for keeping my expectations realistic. I think I’ll give it a go on the cheap wheels for experience, but I’ll likely leave it to pros if I ever invest in a quality bike.

If you only have to fix up one, maybe two, bikes you can grab a bunch of Aliexpress tools and get going:

https://www.youtube.com/watch?v=DV_gX-C7RDE

Those were fun videos. Lots of these tools seem like they would be good enough to try out on junk bikes to learn what it worth doing on my own vs. just sending the bike to the shop. Thanks.

I had the same problem and just went to a frame with disc brakes and never looked back.

the only other thing like that I can think of is if your derailleur hanger is bent you might not be able to perfect the derailleur operation.

For the first pass, I’ll see how well I can tune the existing hardware. The derailleur hanger looks maybe slightly bent. Hopefully I can at least improve it a bit. I’ll definitely consider disc brakes for the next bike.

you don’t have to get disc brakes either. you can true the wheel in the frame with temporary zip ties to guage distance and a spoke wrench, with the bike upside down or in a stand. I just hate doing it enough to not want to do it to the degree required for brake performance is unaffected.

I would recommend even just a cheapo spoke tension meter from aliexpress or something to make sure you dont over tension any. I like to oil the spoke nipples then loosen or tighten them all to be about the same before starting, and then just get it as close as I can without going too high. too high depends on the spoke guage mostly but if the bike has rim brakes they are probably pretty thick and can take more than the literal toothpicks my current bike has which I have snapped a few of.

Down the line if you do get a bike with disc brakes, cable pull IMO doesn’t offer enough performance improvement to be worthwhile but hydraulic introduces more maintentance procedures. I’ll personally take it over rim wear and truing affecting brakes but it is potentially troublesome work. I have also found that even common aliexpress brands for hydraulic brakes are on par with the name brands in performance and reliability at a fraction of the cost, excluding the absolute top of the line which after testing I don’t feel I’ll ever need anyway.

The absolute best thing I ever did in regards to figuring out bike maintenance was to buy a really crappy bike and just try to fix it, similar to what you’ve done. I went into it with the attitude of “if I break stuff, that’s fine, it was super cheap and old anyways” and wasn’t imagining I’d actually get a sound bike out of it. I used park tool YouTube videos mostly, and from that bike (and a few others) I learned how to do pretty much everything maintenance-related short of redoing the seals in a mountain bike fork (and that’s likely coming up soon). Wheel truing is tough but absolutely doable - again, but a really cheap bike (marketplace special), take the wheels off and apart, and just try to get them back together - that’ll force you to true them. Park tool again was an awesome resource for that.

You’ve hit the nail on the head. This describes my mindset. Thanks for the encouragement.

For sure! I’m not always the best at responding immediately, but if you’ve got any other questions, feel free to chat me.

I definitely didn’t start with truing wheels and adjusting bearings but I tried it when the need arose, it is totally doable. Be careful, watch YouTube videos, get the tools you need, and give it a shot. Spoke wrenches and cone wrenches are cheap. I didn’t bother with a tension gauge, just compared the pitch before and after to get to the right ballpark