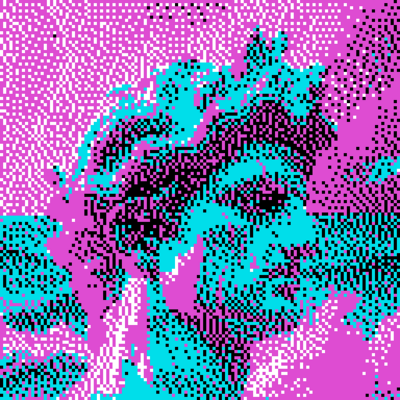

This is a sidewalk grip where it ramps up from the street. I noticed that all of them have the same melt pattern. Low traffic area when no one was out.

Just curious if anyone knows why

Here is what the underside of that particular plate looks like. The metal heats up faster than the concrete as the temperature rises, so the parts with thicker metal melt faster.

Wow, a lot people knew the answer. You even managed to find an image.

Mind blown.

Thanks everyone!

Yep, Lemmy is a pretty neat place!

This is the kind of thing I felt the Fediverse was missing that Reddit had, the braintrust. The power behind r/whatisthisthing. The ability to say “Forensic paleo-opthalmalogists of Reddit…” and get five credible answers. Because a cross section of the entire human race was there. The Fediverse is populated mostly with a self-selecting group of mostly left leaning mostly FOSS enthusiasts so the variety in walks of life wasn’t here yet. This seems to be improving.

It’s pretty much my favorite so far.

Mbin is pretty cool too. Bless the Fediverse.

Underneath the cover there is reenforcement bars in that pattern so there is more mass to conduct heat

But why are they not dick shaped?

Life is cruel and pointless.

Have we considered the snow fell in that pattern? 😲😂

This is the real answer

Snow is simultaneously a particle and a wave. What you’re seeing is the destructive interference resulting from its wave-like behaviour.

The material underneath the top layer will impact how the material temp changes.

It looks like it has some underlying material that is in the square and X shapes that is either retaining heat at a different rate that the surface material or possibly absorbing heat from the warmer ground mass that isn’t as cold as the surface and it is enough of a difference for the snow to melt faster there than the surrounding area.

Because the image of snow cannot be found

Because that’s where the treasure is just start digging.

This picture had me tripping for a good minute thanks.

So that it’s easy to see that there’s a little bit of snow on it as it melts and know it might be slippery.

In addition to the possibility of reinforcement bars it could also have to do with the thickness of the tactile pad or it could have recessed spots underneath (to save on material if it was injection molded) that could create an insulating air gap.

I’d assume there is a heating element under there, probably tied into the streetlight.